gemini NGM represents a large grinding volume in a compact machine with efficient automation. The possible configurations range from high-powered flute grinding to profiling of hobs with high-frequency relief grinding. Generous axis travel don’t just cover the workpiece dimensions, but allow plenty of space to include processes such as dressing, measuring and loader access.

Remarkable features of the gemini NGM are power, mechanical and thermal stability and absolute precision. The dynamically relevant axes can be configured with linear motors, supporting oscillating processes or the rapid change over of auto loading or dressing processes rendering the work effortless.

Thanks to the compact machine design, the high-performance gemini NGM is also highly efficient. The robot compartment is located very close to the tool holder. Tools are changed reaching through the rapid collapsing doors in seconds. The loader space can be conveniently observed from the outside. The swiveling control console allows accessibility to make loading or creating production jobs easier all around. The wheel magazine for 8, 14 or 24 wheel packages with wheels of up to 250mm (10″) in diameter offers absolutely no limit for designing complex grinding processes.

- 5 axes for the production of high-quality precision tools, available with linear motors.

- Optional: Robot or gantry loader, for 2 to 10 pallets

- Integral optical profile checking

- Loader for 8 or 48 grinding wheel sets

- Stroke X: 16 inches (400 millimetres)

- Motor driven grinding spindle of up to 43hp/32kW

Models available for High dynamic relief grinding, tap production, forming tools & Gear hob cam-grinding, heavy production

• NGM Universal machine

• NGM TAP Production of threading tools

• NGM GHP Gearhob profiling

• NGM F-Type Rotary table, production of cubic parts, edge length 350mm

Applications for the Gemini machines

End mills – Radius end mills – Ball nose end mills – Sinus-edge end mills – Roughing end mill – Profile end mills – Form disc cutter – Profile drill – Form reamer – Shell mill – Band saw cutter – Disc end mills – T-Slot cutter – Prism cutter – 4-facet drill – T-Slot cutter – Spot drill – Step drills – Countersink – Centre drill – Gun drills – Thread mills – Hobs – Shaper cutter – Bevel gear cutter – Bevel gear stick blade – Reamers – Up-down cutter – Routers – Finger-joint cutter – Cylindrical grinding – Thread grinding – Non-round grinding – Round thread rolling dies – Bone rasps – Femur – Bone saws – Punches – Spline shafts – Globoid curves

See the applications here

See more machines from Schneeberger

Learn more about the company Schneeberger

Axis:

- X axis: 400mm, longitudinal slide, resolution 0.1 micron

- Y axis: 300mm, vertical column, resolution 0.1 micron

- Z axis: 280mm, cross slide, resolution 0.1 micron

- A axis: workpiece holder, free rotary motion, ISO 50, resolution 0,0001°

- C axis: 240°, grinding head rotation, resolution 0,0001°

Control:

- FANUC 3x series, 5 controlled axes

- 15” TFT colour monitor with keyboard and touchscreen, USB 2.0, RS232

Loader:

- Maximum speed and flexibility thanks to 6-axis Fanuc robot, 4 to 18 pallets

- Optional: integrated with gantry axis, 2 to 18 pallets, 320 mm x 320 mm

Grinding head:

- Dual grinding spindle with forced ventilation, for grinding wheels with 50 – 250 mm dia.

- motor spindle water-cooled, ceramic steel, hybrid bearing,

- , 15 or 26 kW (100%), 12, 18 or 32 kW (60%) 1000 ÷ 10,000 rpm HSK50 or 80

Weight: 17,600 lbs – 8,000 kg

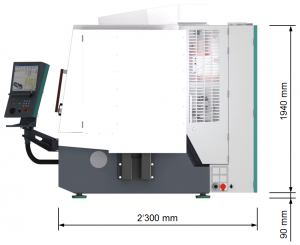

Schneeberger Gemini NGM side dimensions

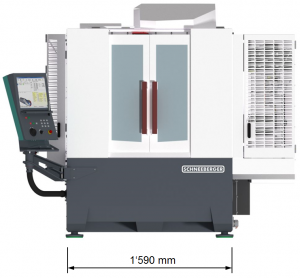

Schneeberger Gemini NGM dimensions