Spline shafts so that the connection fits

Splined shaft connections as per DIN 5464 and 5480 are used extensively in modern mechanical engineering, and they are used to transfer high torque with or without length compensation.

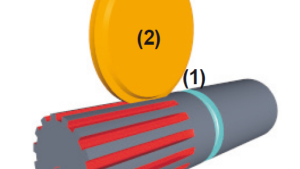

Gear with spline hub profile

Normally, spline profiles are milled with a hob cutter or form milling. Nevertheless, if a very high level of precision is required, then splined shafts are ground.

OKEY AG, which has recently moved to Winterthur, Switzerland, is specialised in the production of splined shafts of this type.

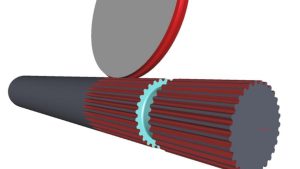

In the new spline shaft module of the Qg1 grinding software, both spline shafts with spline hubs (rectangular) and involute profiles for spline shafts are calculated and displayed in three dimensions. In addition to this, the associated grinding wheel shape is calculated, which is then able to be dressed and used directly at the machine.

In addition to header and footer modifications, bearing and bezel seating are also able to be geometrically projected and, if necessary, the outside diameter of the shaft can be rounded by grinding.

The special feature of this is that the calculated grinding wheel shape is able to be partitioned to a single groove, double groove, or separately to both flanks. While in case of a double groove, speedy processing times are the focus, partitioning the grinding in left and right flanks reduces the grinding pressure and improves control over the grinding process.

Spline shaft with involute profile and bezel seating

Furthermore, this strategy also enables use of two more narrow grinding wheels instead of a single wide one, just in case this is not readily available.

Unwanted arc radius of the groove (1); the diameter of the grinding wheel (2) is too large at the arc. A smaller grinding wheel must be used in this case.

A conformity inspection also checks if the grinding wheels used match the workpiece. If the grinding wheel radius is greater than the target arc radius of the groove, then a warning is issued and the grinding wheel is marked orange.

In case of special shapes, the desired spline form may still be imported in DXF format, of course. Now it is also possible to jump over certain grooves and grind in (partial) segments.

Schneeberger machines suited to spline grinding are: Aries NGP, Norma NGC, Gemini NGM, Corvus and Corvus C-Type.

See more about the range of Schneeberger machines we sell here:

Or read about the Schneeberger company here:

Tags: Aries, bearing, bezel seating, Corvus, form milling, gear, Gemini, grinding machine, hob cutter, Norma, Qg1, Schneeberger, spline, spline shaft