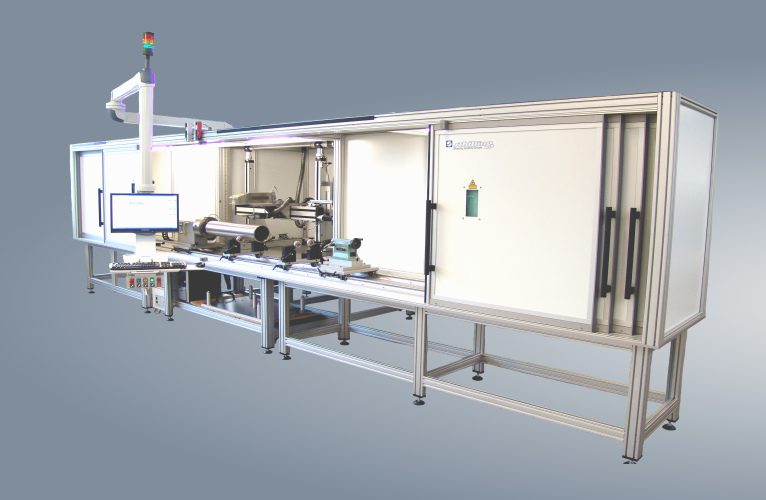

With our many years of experience in the field of special purpose machinery manufacture, we can precisely tailor the marking system to your individual requirements. Those requirements might be for particularly large workpieces or for automatic supply systems. In our special machines we integrate our marking lasers, dot peen and electrolytic marking technology. Furthermore our machines can be integrated into existing production lines. Moreover it is possible to connect them to robot systems. Individual software solutions, such as for instance the connection of our machines to existing data-bases (Majesty, SAP…), complement our product range. Special machines by Schilling are successfully used in different sectors (e. g. automotive industry, machine building, medical industry…). Our customized machines can be operated simply and intuitively.

- Individual Solutions

- Hard- and software Solutions

- Own development, construction and manufacturing

- Feeds, automation…

- Very good knowledge of different branch requirements

For more examples of the customised applications see the main Schilling website here:

Laser Marking on Tubes – Very large and long tubes can be marked with an 8m long laser marking machine. Partially the parts also need to be marked on 360 degrees. The rotary axis can be moved, depending on the length of the parts.

Laser Marking of Air Suspension Systems – Air suspension systems are marked with a DataMatrix code by a Mega-Light F20 and classified as a camera which is integrated in the laser. In each case, sensors check whether a part has been inserted to be marked and if so, the kind of part. Depending on which part has been inserted, the corresponding marking file opens. The parts are marked with the correct information and the camera verifies whether the marking is correct and evaulates the quality of the marking. Every marking is saved in a database for traceabiloity.

Laser Marking of Cylinder Heads – The cylinder heads of an engine are marked with a DataMatrix code by a Mega-Light V40 Laser and verified by a scanner. In each case, sensors check that the correct part to be marked has been inserted.

Dot Peen Marking of Wheels – Wheels are marked with a Mega-Marker and a robot on 360 degrees. The robot removes the wheel from the pallet, moves the wheel under the Mega-Marker and the marking machine marks the wheel on 360 degrees.

Laser Marking of Large Machine Parts – Very large machine parts are loaded on the marking laser with a crane. The roller garage door can completely be opened and closed. After loading the laser data can be started. Then the roller door closes completely. The laser has a very large marking area of 1300 x 1300 x 500 mm.

Dot Peen Marking of Metal Sheets – Mega-Marger with pneumatic z-axis and hold-down device. The metal sheet is pushed onto the table all the way into the stop corner. The marker is pushed with the x-positioning slide to the area to be marked (latching). When the marking process starts, the z-axis moves down approx. 10 mm and the hold-down devide rests on the sheet. The software SchillMarker controls the marking of the part. When marking is complete, the z-axis returns to its basic position.

Electrolytic Marking of Titanium Rods – This machine is used to mark titanium rods along their entire lengths. Titanium rods are available in four different lenghs. The corresponding template is glued onto an aluminium frame, in its basic position, the aluminium frame is at the back. A titanium rod is inserted into the prism. The machine is started. The template frame moves forward and stops over the part. The marking cylinder moves down. A motorized linear axis moves to the right and the rod is marked along its entire length. The marking cylinder moves upwards. The template frame moves to the back and the part can then be removed.

Laser Marking of Heater Cartridges – Mega-Light V40 caminet with lateral openings and brushes with protection against laser radiation for the feed-through of long heater cartridges (up to 2,000 mm length). The cabinet has a pneumatic door opener and closer.

Electrolytic Marking of Cardiac Catheters – New cardiac catheters are marked simultaneously in different positions. The marking consists of a thin or thick line around the catheter. The stations can be moved to the right and to the left.

Laser Marking of Shafts – The shafts are put on the rotary indexing table. The table turns around 180 degrees. The shafts are marked. After the marking the table turns again 180 degrees. The shafts with the marking can be removed.

Dot Peen Marking of Heavy Round Parts – A special large rotary axis for dot peen marking of very large and heavy round parts. The dot peen Mega-Marker is installed in a noise-protection cabin.

Laser Marking of License Plates – License plates are produced with a punch machine and immediately marked with the laser. The special software enables fast, easy and correct laser marking every time.